And its hypotenuse is Ih Square root 92 874932812 1255192704. Just as important gearmotors are designed to work well with a variable-frequency drive VFD which provides enhanced speed control over-load protection and adjustable starting torques.

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Mechanical Design of Mixing Equipment D.

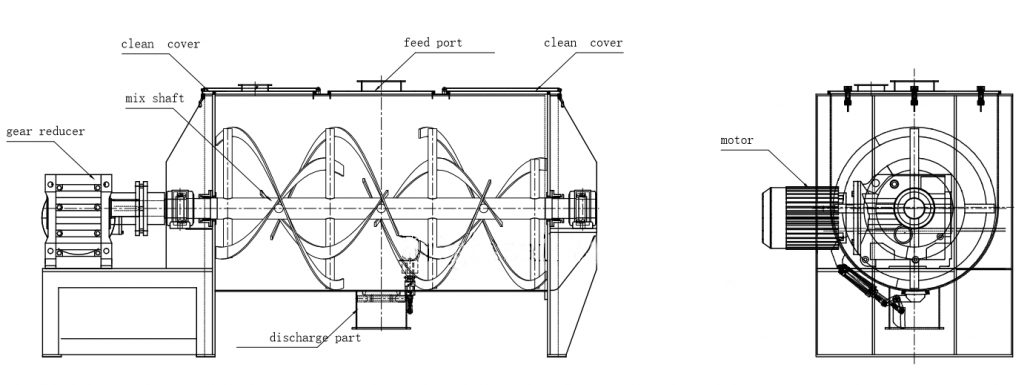

. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing. Equipped with a liquid-tight flush valve Ribbon Blenders built for this type of application can include jacketing around the trough to control product temperature. The mixer consists of a rigid fabricated structure motor gear box mixing drum stirrer and tilting device.

Wear resistance corrosive resistance vacuum filling and. Diameter shaft surrounded by a 18 in. Usually a competent manufacturer of.

Besides different material can also be used in combination. And requires minimal maintenance. The effects of fill height and blade rotation speed on mixing homogeneity have been studied.

BASIC INTRODUCTION 1 Flexible material selection. More robust blenders are available for. Ft 10 HPThis Ribbon Blender built in stainless steel and designed for center discharge is equipped with a control panel designed and built by Ross Systems Controls.

Ribbon blenders can be customized to fit. Industry-wide most standard ribbon blenders can typically handle bulk densities of around 35 lbscuft. Model 42N-515 Ribbon Blender 515 cu.

Examples include ready-to-eat soups pasta sauces pet food and the like. 1 12 in. In some cases a very large blender might be suitable.

All experiments are performed in a 5 ft 3 laboratory-scale ribbon blender provided by Eirich Machines Gurnee IL in an environment with constant temperature and humidity 73 F 40 RHUnless otherwise noted experiments are performed using a 5-spoke ribbon blade with a 25 in. A wide variety of configurations for either batch or continuous mixing are available. The design of the Jas ribbon blenders can incorporate features required for a customers product or process such as.

Ribbon blenders directly driven by a gearmotor one-piece motor reducer are generally recommended over belt- or chain-driven designs. Model 42N-25 Ribbon Blender 25 cu. In addition compared to other types of blending equipment the Ribbon Blender is usually.

This will depend on the amount of material you are mixing as well as the speed with which it must be mixed. The blender which reduces the ribbon blenders overall space requirement. RIBBON BLENDER The Jas ribbon blenders are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending.

Lab scale ribbon blender The Laboratory Mixer is designed for uniformly mixing of dry and wet material and especially suitable for Pharmaceutical Food and chemicals industries. 1 14 in. To answer all of these questions with associated calculations is not a simple task since the mixer design involves many variables and design decisions.

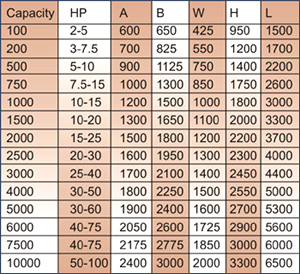

Al-though mixer design begins with a focus on process requirements the mechanical design is essential for successful operation. This article provides definitions of the different types of bulk densities and explains the differences between them. Capacity - 175 HP.

Ribbons and support arms are clean and effi cient. Its reliable rugged design can be built for capacities over 1000-cuft. Ribbon Blender is primarily designed for use with dry materials although gas and liquid streams can also be introduced.

Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials. Inner ribbon and a 14 in. Perimeter 2875 pi 87493281.

Material can be chosen from carbo steel manganese steel ss304 316L and 321. Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle. Bulk density of material is one of the most important physical properties of material to be considered while designing blenders.

Some blender selection and specification considerations The desired batch volume determines the size of the blender but product bulk density determines if a standard or heavy-duty model is required. 21-1 INTRODUCTION Mixing equipment must be designed for mechanical and process operation. By the same method you can get the outside diameter the 9 in OD is 2827433388.

Abbe designs and manufactures ribbon blenders which are ideal for blending dry free-flowing solids with bulk densities up to 70 pounds per cubic foot 11 gcc depending on material characteristics including particle size size distribution and particle shape morphology angle of repose cohesiveness and moisture level. We have built nearly 50 of these stainless steel jacketed and internal. The mixing drum complete with stainless steel body stirrer.

Material is different between the part contact with the raw material and the parts dont contact with the raw material. All limit switches must be wired into the motor control circuit to disconnect power All stainless steel construction when the grates are removed or the covers opened depending on the blender design. The volume and profile of the ribbon blender are the most important aspects to consider when selecting your ribbon blender.

Blender selection and design depends on several factors including the properties of material to be blended. Design considerations had been studied during Analytical. However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon.

In this case is 3995402467. This measure is the depeloved perimeter of the internal diameter of the washer so Ihpi. Proportions into large stocks.

Common ribbon blender processes.

Ribbon Blender Mixer Animation Youtube Recycling Machines Blender Mixer

Shell Tube Heat Exchenger Wiki Mini For Chem Heat Exchanger Chemical Engineering Oil And Gas

Ribbon Blender Capacity Calculation Ainuok Machinery

How To Select A Ribbon Blender Powderbulksolids Com

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender And Mixer Saintytec

Ribbon Blender Ribbon Mixer Design Calculation And Selection

0 comments

Post a Comment